To remove a crack-like flaw near the base of a silo shell, the customer replaced the region surrounding the crack with a flush patch. However, due to the local heat produced during welding, the silo shell in the general region of the flush patch became distorted upon cooling to ambient temperature. Therefore, a Fitness for Service (FFS) assessment was performed to determine if the silo was adequate for continued service under design loads with the distorted geometry of the shell.

The silo was analyzed using elastic-plastic Finite Element Analysis (FEA) per API 579-1/ASME FFS-1 code. The model included the deformed shape of the shell as defined by measurements provided by the customer. Based on the shell distortion and the design loads for the silo, the primary mode of failure considered for this analysis was buckling.

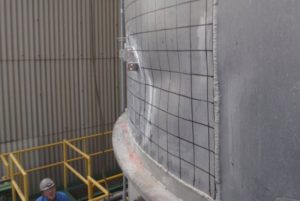

- Photographs of the Actual Shell Distortion

- Photographs of the Actual Shell Distortion

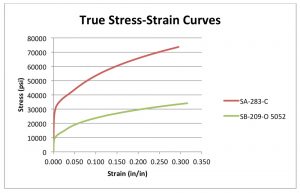

- True Stress-Strain Curves for the Materials

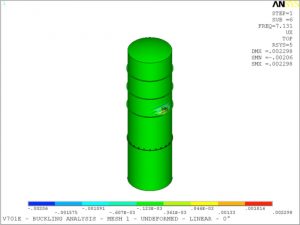

- First Local Buckling Mode Shape for Shell

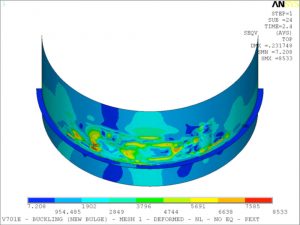

- von Mises Stress Profile in Buckling Section