The scope of the project was to perform Fitness for Service and rerate calculations to analyze the adequacy of a distillation column. Distillation column has been in service for several years. The customer requested for additional corrosion allowance of the distillation column for several more years. Rerate of the distillation column included the shell, the heads, the skirt sections, all the nozzles with corresponding flanges, and the support trays. Calculations included the effect of wind bumpers, platform clips, and pipe supports. The structural adequacy against buckling was verified using Finite Element Analysis (FEA) for the increased corrosion allowance. The determination of structural integrity utilized both Eigen value buckling and nonlinear buckling analyses.

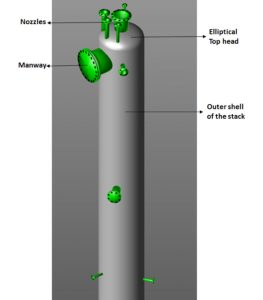

- Top of the distillation column

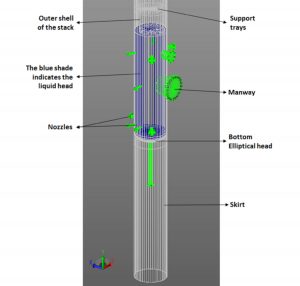

- Bottom part of the distillation column

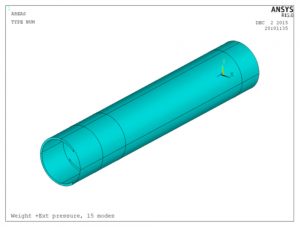

- Overview of the model used in buckling analyses

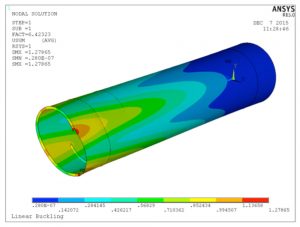

- First buckling mode: The deformation of this model was used in the nonlinear elastic-plastic analysis to determine the adequacy of tray ring supports and the tray ring support to shell weld.

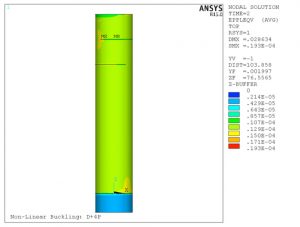

- Von-Mises plastic strain in the column