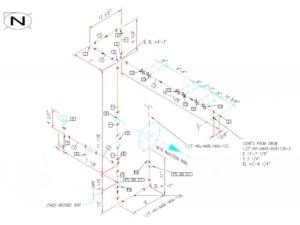

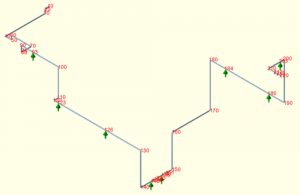

Field measurements were performed for a new chlorine abatement unit pipeline route in order to expand production for a chemical company. Initial pipe routing sketches for natural gas, hydrogen, chlorine, and nitrogen lines were modeled using AutoCAD Plant 3D. Pipe supports were also included in the 3D model for each pipeline from the customer interface point to end user. The routing information, types of valves, switches, instrumentation, and supports were included in the isometric drawings. Pipe stress analysis was performed based on ASME 31.3 to determine the adequacy of the supports using CAESAR-II.

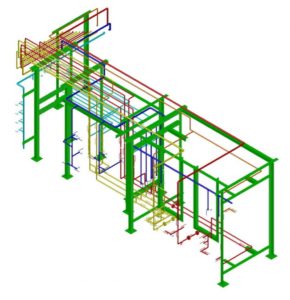

- Chlorine Abatement Unit Model with Nitrogen, Natural Gas, Hydrogen, and Chlorine Pipe Routes with Valves, Instrumentations, and Supports

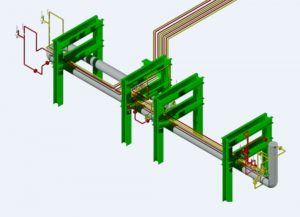

- Injection Ring Inlet of the Chlorine Abatement Unit

- Metering and Switching Station Modeled for the Chlorine Abatement Unit

- Isometric Drawing of the ½” Hydrogen Line to the Injection Ring

- CAESAR-II Pipe Flexibility Analysis for one of the Pipelines in the Chlorine Abatement Unit