Fabrication Technology & Training

Openso Fabrication Technology

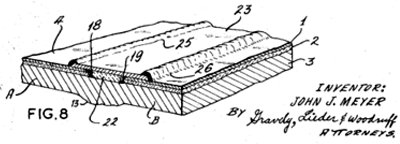

- Tri-Clad reactors are being utilized ever more often in Acetic Acid Plants and other similar corrosive process applications

- Openso Engineering is one of the few companies that has the design and manufacturing knowledge in the world for Tri-Clad construction. As tri-clad design offers greater potential for total reliability and longevity than bi-clad. Safe and continuous operation of the unit is ensured.

Openso Engineering has successfully transferred tri-clad fabrication technology to fabricators.

- TITANIUM AND ZIRCONIUM SOLID

- TITANIUM AND ZIRCONIUM CLAD

— Single Integrity

— Double Integrity - TANTALUM CLAD

- HASTELLOY B-2 QUENCH ANNEALED WITH PLYWALL WRAPS

Fabrication Training

SURVEY OF FACILITIES

- Factory

- Design Department

FABRICATION INSTRUCTION

- Heat Treatment

- Testing

- Repair Methods for Reactive Metal Clad Vessels

- Procedure Development

- Fabrication Problem Solving

- Failure Analysis of Welds

- Repair Recommendations for Existing Pressure Vessels and Heat Exchangers

DESIGN DEPARTMENT TRAINING

- ASME/TEMA (Section VIII Division 1, 2 & 3)

- Design and Analysis

- Fabrication Details

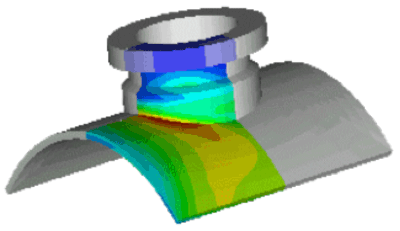

- Finite Element Analysis

- General Techniques (see section A.1.a)

- General Problems (see section A.1.b.)

- Fitness For Service (see section A.3)

FORMING FOR FABRICATION

- Analysis of Forming Problems

- Specification Writing and Review

NDE PROCEDURES

- Specification Writing and Review

- Sequencing of NDE and Testing

HEAT TREATMENT

- Specification Writing and Review

- Analysis of Heat Treatment Charts & Procedures

INVESTIGATION OF FABRICATION PROBLEMS

At Openso Engineering, we customize our training services to meet your company’s specific training needs. All courses are presented by industry experts. In-Company training represents a cost-effective, timely and flexible training solution. We also offer our clients seminars and training at Openso’s location. Your company’s privacy and security are guaranteed.