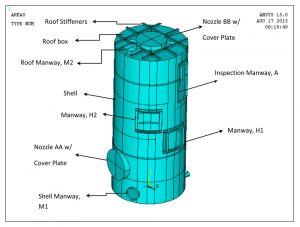

The scope of this project was to design and analyze a New Dryer Scrubber with the following design conditions: atmospheric pressure -35” of water column partial vacuum at 230ºF plus max liquid level of 4’-8”. The tank and nozzles of the Scrubber were designed per API 650. The preliminary tank design was based on longhand calculations, and then analyzed using Finite Element Analysis (FEA) to verify the adequacy of the tank under the design conditions (nozzle loads and wind/seismic loads were provided by the customer).

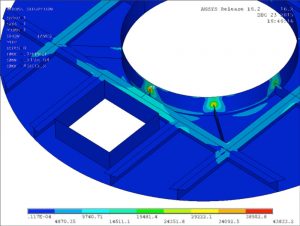

- von Mises Stresses at the Outlet Nozzle on the Tank Roof. Max Stress Occurs at the Junction of the Web Plate and the Nozzle Neck.

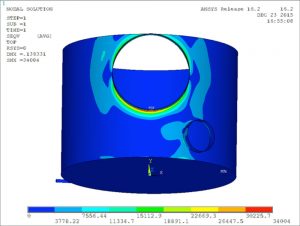

- von Mises Stresses at the Inlet Nozzle on the Tank Wall. Max Stress Occurs at the Junction of the Nozzle Neck and the Tank Wall.

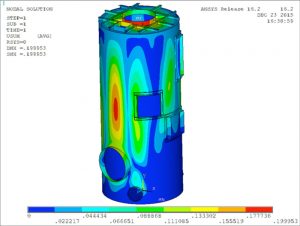

- Maximum Displacements can be Seen at the tip of Outlet Nozzle on the Roof and Midway up the Tank Wall.

- Replacement Scrubber Tank per API 650